The market for pyrometers is growing rapidly due to an increased industrial focus on non-contact temperature measurements and portable digital instruments.

A pyrometer is a non-contact thermometer that measures the temperature of an object based on the radiation from the surface of the object. Most commonly, the radiation is measured in the infrared wavelength range. At a given temperature and wavelength the object only emits a fraction of the heat as radiation. This fraction is called emissivity and must be known for the object to measure the surface temperature.

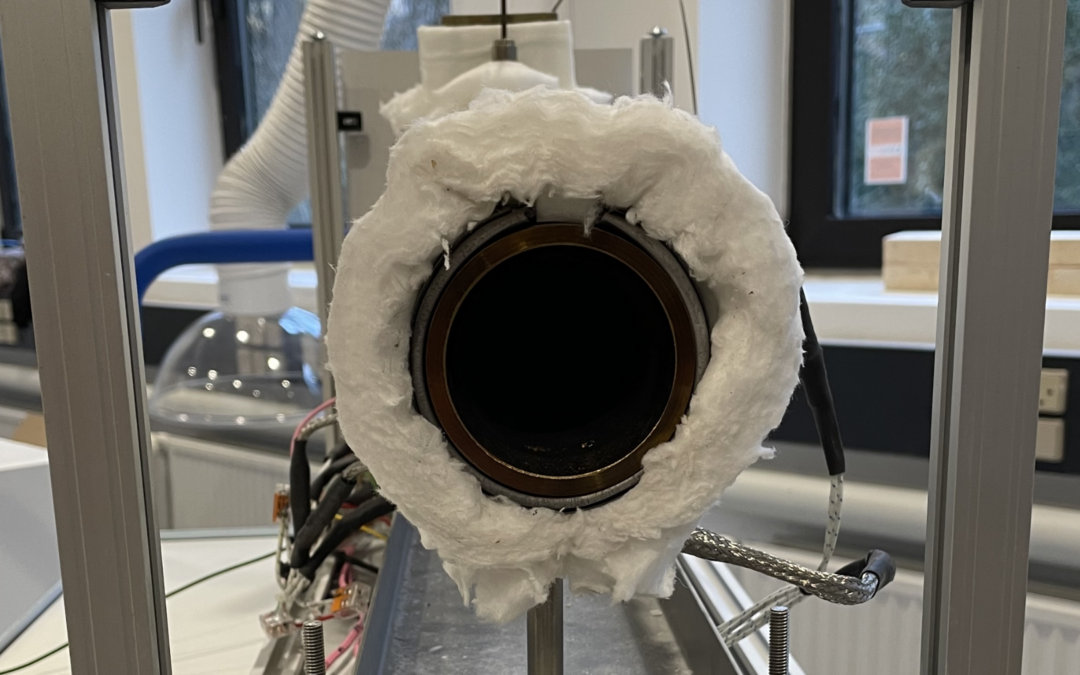

Obviously, pyrometers need to be calibrated to provide accurate temperature readings. The calibration is done by aiming the pyrometer at a black body source that is specifically designed for calibration. The core component of the calibration source is the temperature controlled black body cavity, which is typically around 400 mm long and 60 mm in diameter. The emissivity of the black body should be as close to 1 as possible, i.e., it is designed as a light trap with high emissivity coating on the walls to obtain an effective emissivity of 0.9997. It is furthermore important that the temperature of the black body is homogenous across the entire black body. To obtain a homogenous temperature, the black body cavity is immersed in a liquid circulated quickly around the cavity or a cavity designed with heat pipe walls.

DFM has been offering calibration of non-contact thermometers using black body calibration sources for many years. So far, a water heat pipe black body has been used for non-contact temperature calibrations in the range 50 – 250°C. To replace this existing set-up and extend the temperature range, DFM has now designed and built two new flow cell based black bodies in-house. The temperature range is extended to 23 – 500°C using a silicone oil below 150°C and a molted salt above 140°C. A specially designed double action stainless steel pump with sapphire bearing circulates the liquid around the cavity. The black body temperature is measured accurately by a reference thermometer probe placed in the liquid.

The new flow cell based black body has been proven to offer the same or better performance than the old water heat pipe system. The new system furthermore enables a fast-heating rate of 7°C/min and excellent temperature stability significantly better than the 0.1°C typical resolution of commercial pyrometers.

The two new flow cell based black bodies cover the temperature range between vertical black body cavity inserted in thermostat baths at low temperatures (-80 – 23 °C) and sodium heat pipe black body (450-1070°C).

The project is supported by funds from Danish Agency for Higher Education and Science.

DFM is one of the seven Approved Technological Service (in short “GTS” in Danish) institutes in Denmark.